Total PCB Solution

With over 20 year of experience we can cover all your needs from PCBA Design & Development, Prototyping and Mass

Manufacturing in one of the most competitive manufacturing environments worldwide.

Design & Development

Our PCB design is done by an in-house CAD team and our entire design and production process takes place at our factory in the Philippines. Engineering our circuit boards in the Philippines helps us to ensure quality, efficient costing and ease of communicating in English to offer the fastest and the most competitive package in our industry.

Our design and development process begins with a deep understanding of our clients' needs and market demands. We conduct thorough research and analysis to identify opportunities for innovation and improvement. Our team of experienced engineers and designers then works collaboratively to develop creative and effective solutions that meet these needs.

One of the key strengths of our Design & Development Group is its ability to review and analyze existing products critically. By continuously assessing the performance and features of our products, we can identify areas for enhancement and implement improvements that enhance functionality, reliability, and user experience. This proactive approach ensures that our products remain at the forefront of technological advancements and market trends. We are hereby proud partner of leading manufacturers in the industry such as Microchip, ST, Atmel, NXP, freescale, Vishay and many more.

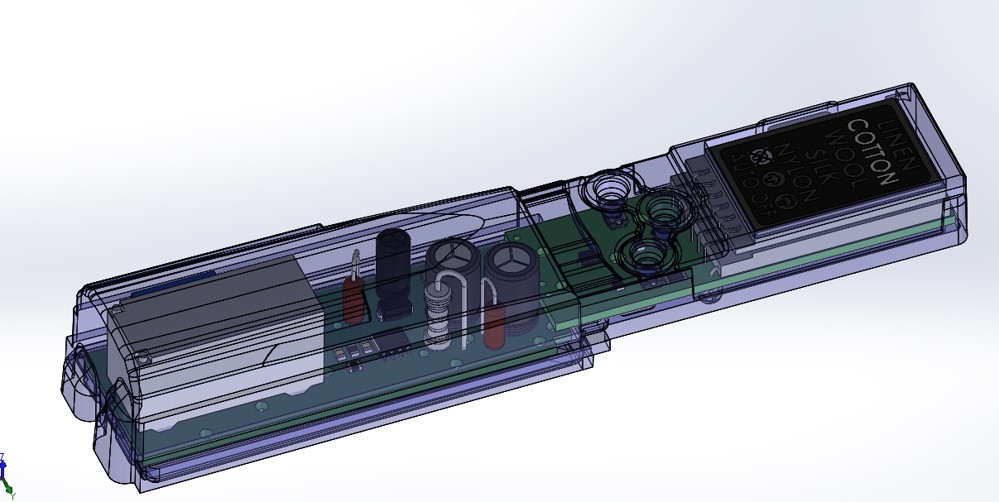

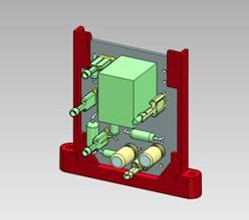

Prototypes

Our state-of-the-art prototyping facilities enable us to bring designs to life quickly and accurately. We use advanced prototyping technologies and internal 3D printing capabilities to create high-fidelity models that allow for thorough testing and validation. This iterative process helps us refine and optimize designs, ensuring they meet all performance and quality standards before moving to mass production.

Homologation Support

We offer a comprehensive support that help you to obtain approval for your products. This entails the completion of needed documentation relating to your new or updated PCBA as well as communication with major certification bodies such as UL and VDE.

Manufacturing & Procurement

With our long history in manufacturing PCBA in the Philippines for globally leading companies worldwide, we are able to manufacture your products at high efficiency and the most competitive manufacturing environment in Asia-Pacific – ranging from 2.000 up to 10.000.000 units per year. Besides ensuring most competitive pricing, we live on the Zero Defective Parts Per Million (DPPM) mindset in everyday operations heavily supported by strict traceability and verified quality standards. Our capabilities include, but are not limited to:

- Surface Mount Technology

- Automatic Screen Printing

- Solder Paste Inspection

- Auto Optical Inspection (AOI)

- In-circuit Testing (ICT)

- Solder Reflow (8-10 zones)

- 3D PCB X-ray

- Solder Wave

- Thru Hole Assembly

- Manual Soldering

- Conformal Coating

- Low pressure injection moulding for PCBA sealing

- Functional Testing

International logistics

Our strategic location inside a 55,000 square meter highly industrialized business park in the Clark Special Economic Zone in the Philippines provides us with significant logistical advantages. The proximity to Clark International Airport and a one-and-a-half-hour drive to the Manila and Subic international seaports enable efficient distribution and logistics, serving international markets such as the US, Europe and Asia-Pacific and ensuring timely delivery to our international clients.

Based on our long-term experience, we are versed in efficiently managing the global export process, also including CTPAT in the US, and completing documents to ensure that our customers can avail for potential preferential duties under trade schemes such as Generalised Scheme of Preferences (GSP) in the EU.

Optimization

As special service for our customers, we also offer to review existing product designs to reduce costs, improve the supply chain & find possibilities for technical advancement/innovation. Some of the actions include:

- Choice of proven alternative components and component suppliers from established purchasing network in Asia and Asia-Pacific

- Reduction of component count

- Reduction of assembly costs

- Application of low pressure moulding technology for PCBA sealing

- Change of raw materials

- Review of test criteria to adjust design to actual end user scenario

- Give clients access to favourable purchasing agreements made by H3 Technology

Mobile Charger PCBA

Motor Control PCBA

Climate Control/Thermostat PCBA

Electric Oven PCBA

Steam irons/garment steamer PCBA

Coffee maker PCBA

Driving innovation

Our in-house PCBA development team is our passion.